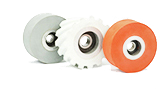

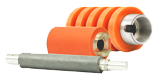

Rubber roller ring

Dimensions

Rubber roller rings are generally large size:

diameters included between 42mm and 90mm, lengths ranging from 600 mm up to 2000mm.

Assembling

They are made from an iron pipe equipped with bearings or even back-old bearings assembled on a central rod.

They can be coated by any rubber type depending on the roller application. We are able to coat commercial rollers, on account work too.

Applications

Rubber roller rings find applications in handling, dragging and calibrating machine sectors.

Mounting steps

We make the rings and fit them on the pipe, and thanks to our experience and technical solutions, we are able to offer such items with rings tightly sealed on the pipe (though not vulcanized).

Reduced Costs

Rubber roller rings make it possible to manufacture any type of roller at lower costs compared to vulcanization.

Fast Repair

Rubber roller rings secure an easier and faster repair in the event of misuse, you just need to change the damaged or broken rings.

Easy Repair

The customer can easily repair it too, inside his own factory.

Ensured Resistance

Despite their great length, our rollers possess both concentricity and tolerance on the external diameter within ± 0.1mm

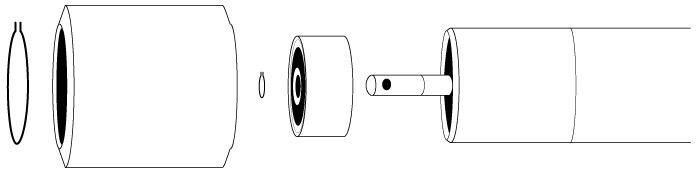

Step 1

Component preparing

Step 2

Metal components mounting

Rod, pipe and bearings are assembled and locked by seegers.

Step 3

Locking metal components

All components are to be assembled and fastened properly.

Step 4

Rubber ring assembly

The rings are fitted on a pipe by means of compressed air.

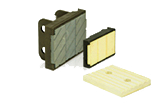

Vulcanized Rollers

Vulcanized rollers are generally small, varying their diameter from a few millimeters to 100mm and their length ranging from 20 mm up to 580 mm.